Pneumatic Knocker

Manufacturer & Supplier

Pneumatic Knocker

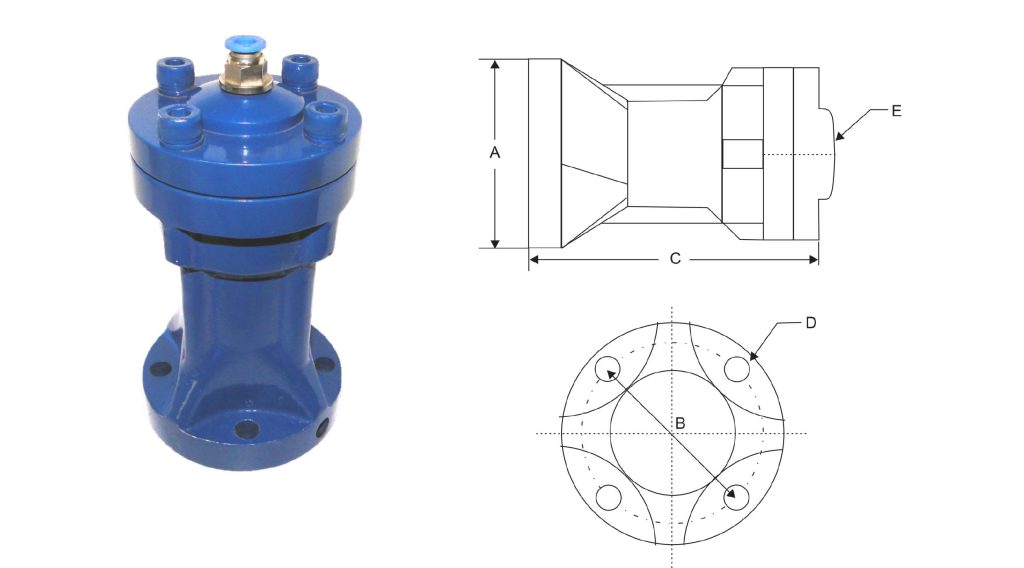

We are Pneumatic Knocker Manufacturer in Gujarat, India. We manufacture and provide a wide assortment of material handling systems to cater to various industries. We use premium quality raw material. The key attribute of an impact hammer is the Air knocker. It has a strong magnetic field and a powdering effect. Low air intake, low movement costs, and a positive energy-saving impact are all advantages. The time between strike intervals may be modified. The standard is consistent, and there is a low failure rate. The style is unique and the arrangement is basic. Piston effect resistance, chic (customizable explosion). A effective auxiliary machinery for powder manufacturing production lines, it is widely used in pesticides, pharmaceuticals, chemicals, cement, dyes, pigments, food, electronics, building materials, minerals, environmental protection, and other industries.Features

- Highly strengthened aluminum body

- Low frequency / continuous impact model, sudden activation / deactivation is allowed

- Frequency and amplitude of impact can be adjusted as required

- Direct impact onto target object to produce the optimum vibration feedback.

NEED MORE INFO?

You can learn about silo blockage solutions.

Following points covered :

● What is a Pneumatic Air Knocker?

● How does it work?

● When should you use it?

● When is it not advisable to use it?

● Bin activator

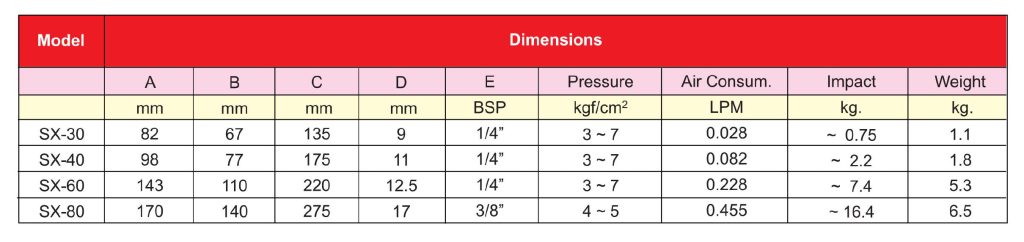

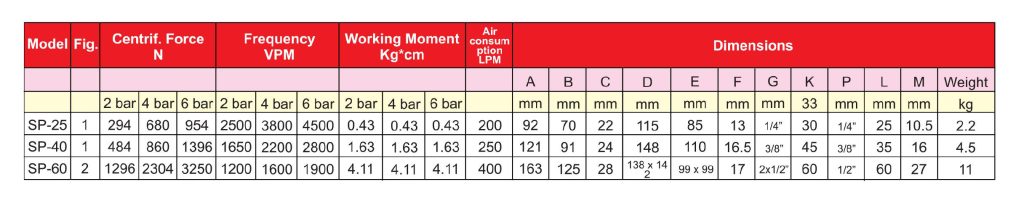

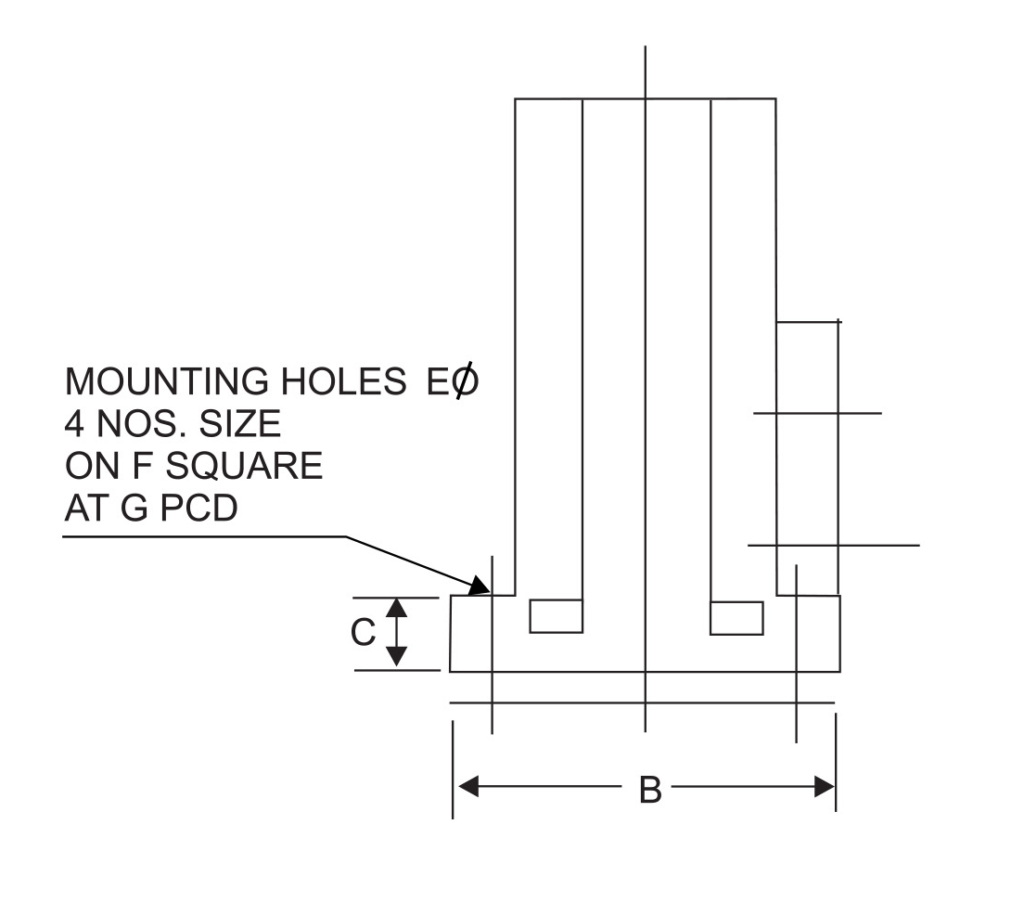

SP Piston impact vibrator

Properties

- Continuos Duty

- Working temperature: 20 °C to 110 °C

- Noice: Approx 100 dB

- MOC: Cast Iron Body ( Power Painted )

- Aluminum cover

Application

- Cement & Concrete

- Sugar

- Wet Sand

- Salt

- Chemicals & Minerals

- Detergents

- Fly – Ash

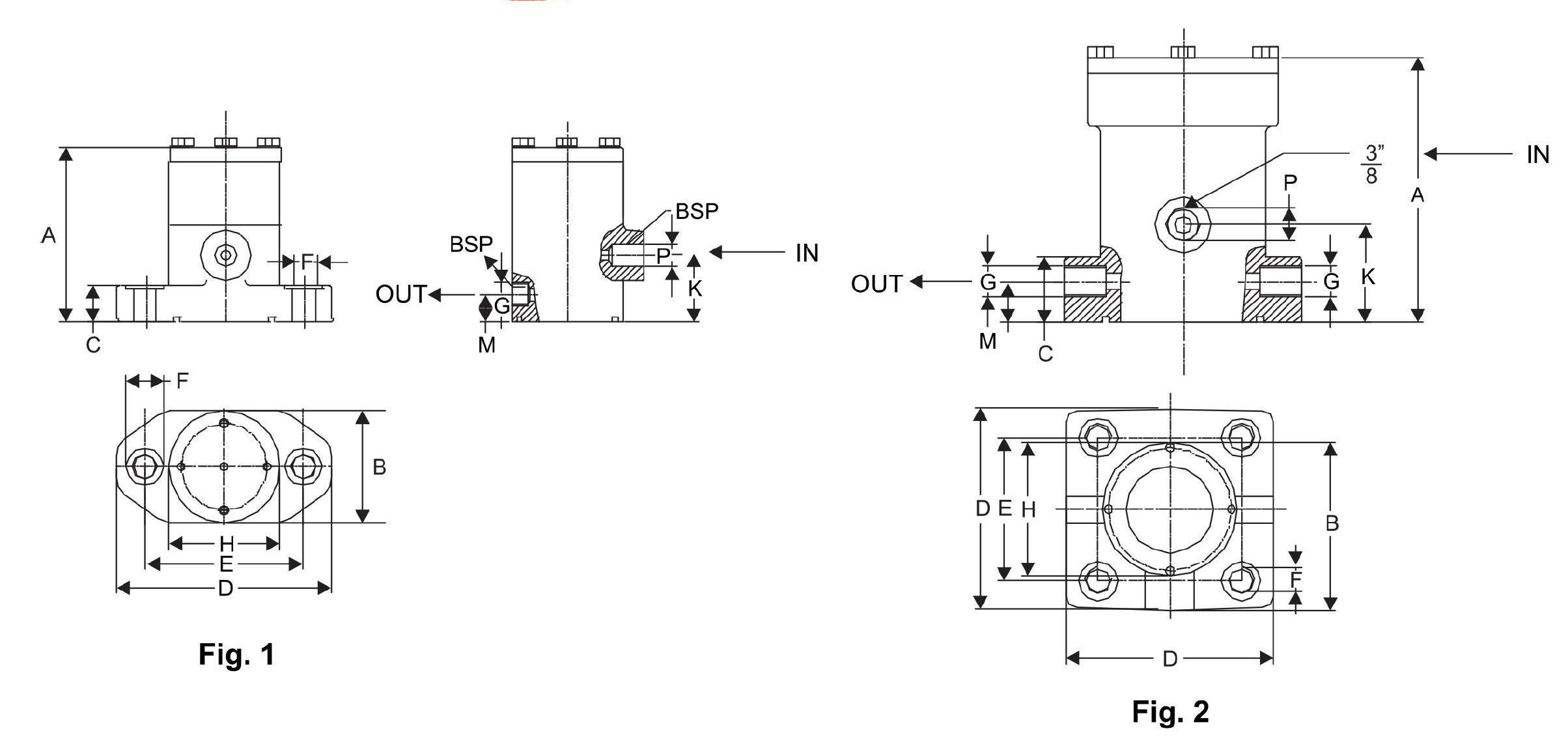

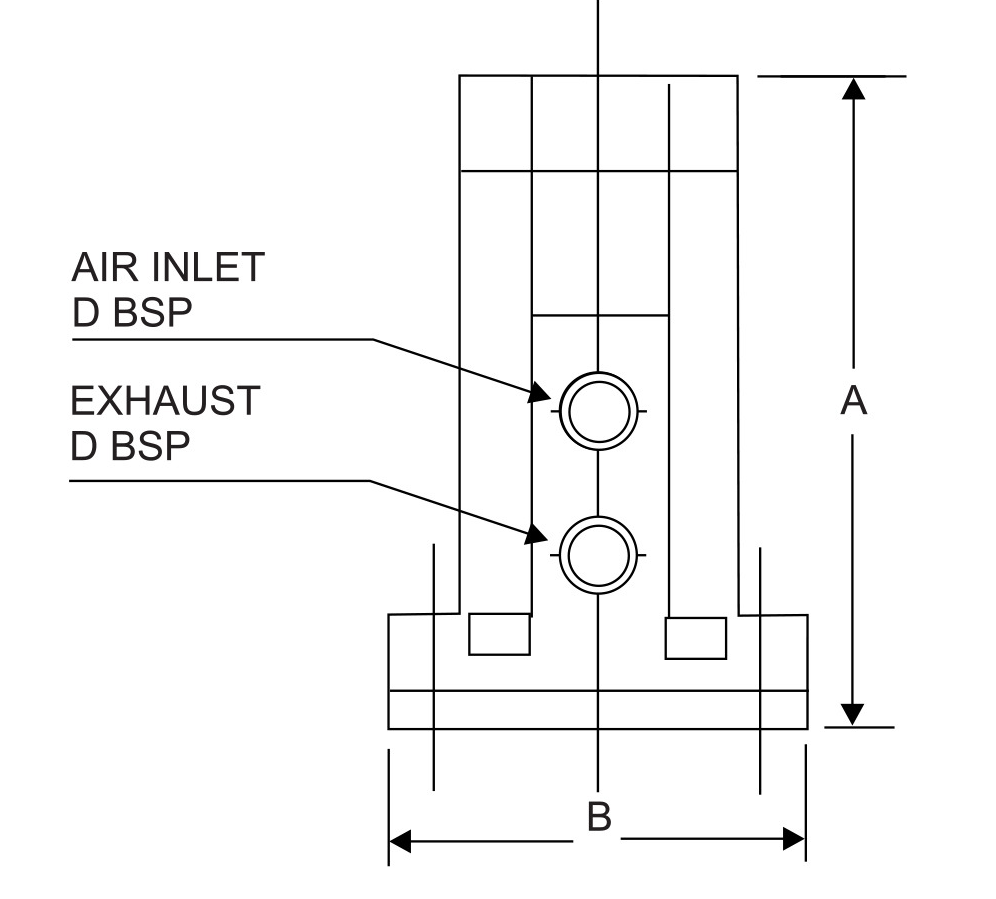

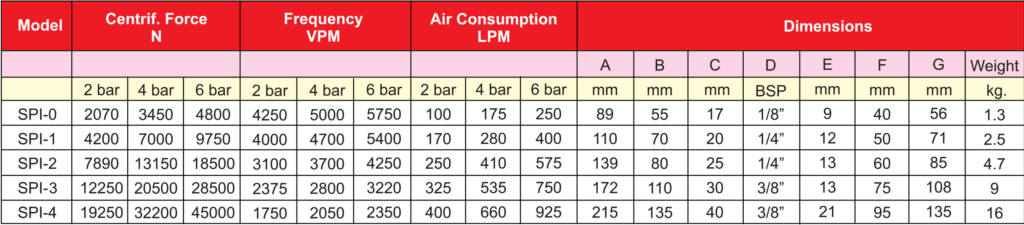

SPI Pneumatic Piston Vibrator

Benefits

- Maintenance free

- Cost effective

- Unaffected by dust, dirt, moisture and even splashing water

- Self cooling – suitable even for hot ambient.

Applications

- Dislodging materials sticking & clinging to walls of storage containers, cyclone separators, bag house hoppers.

- Promoting material discharge from tote bins, bulk tankers, bottom discharge rail cars etc.

- Clearing clogged pneumatic conveying lines.

- Imparting vibrations to moulds & containers for material compaction, densification and settling and help reduce packaging cost.

- As pneumatic hammers for making or breaking assemblies.

- Unlocking bottles, cans, caps and similar objects on or in their vibrating conveyors, tracks and vibrating feed cages.

- Vibrating funnels to hasten material transfer in to narrow necked pharma& cosmetic containers.

- Driving small screens for separation & grading and vibratory test & material settling / densification tables.

You can see more videos of our products and Trials on our YouTube channel

Related Products

We are Pneumatic Conveying system Manufacturer in India. We manufacture and supply a wide…

We are Rotary Air Lock Valve Manufacturer in India. We manufacture and supply a wide…

Was this article helpful?

YesNo