Learning Pneumatic Conveying System with Chemical Engineering

Fluid Flow Operations

Chapter-1 Flow Past Immersed Bodies:

- Introduction

- Fluidization

- Types of Fluidization

- Fluidization Characteristics – Fundamentals

- Minimum Fluidising Velocity

- Minimum Fluidization for irregular shape particles

- Minimum Fluidization Velocity in terms of Terminal Setting Velocity

- Problems

- Solution

Fluid Flow Operations

Chapter-1 Flow Past Immersed Bodies:

Introduction

The Situation where the solid is immersed in, and surrounded by, fluid is the subject of this chapter.

There are 3 possibilities for flow past immersed bodies:

- Fluid at rest and the solid moving through it

2. The solid at rest and the fluid flowing past it

3. Fluid and the solid both moving.

The relative velocity between the fluid and solid is important.

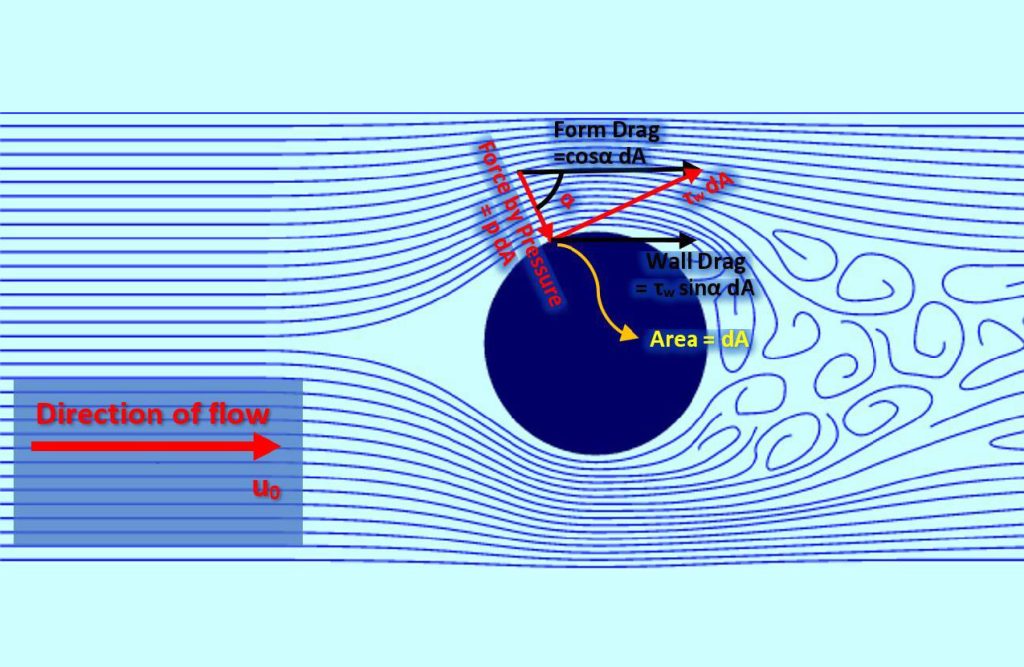

Drag

The force in the direction of flow exerted by the fluid on the solid is called

drag. By Newton’s third law of motion, an equal and opposite net force is exerted by the body on the fluid.

When the wall of the body is parallel with the direction of flow, as in the case of the thin flat plate the only drag force is the wall shear τw.

However, the wall of an immersed body makes an angle with the direction of flow. Then the component of the wall shear in the direction of flow contributes to drag.

An extreme example is the drag of the flat plate perpendicular to the flow.

The total drag on an element of area is the sum of the two components.

- The total integrated drag from wall shear is called Wall Drag.

- The total integrated drag from pressure is called Form Drag.

Drag Coefficients

Drag coefficient is used for immersed solids.

The drag coefficient,

- You can understand the Dimensions Of The Evaporator from the image easily.

Liquid Volume indicates the Minimum Amount Of Liquid you have to keep inside the

Evaporator so that the Agitator Motor can give Maximum Efficiency For Heat Transfer

with the help of an Anchor Agitator.

In this example, you can select a motor with 3HP power and the range of rpm can be between 12 to 15

rpm.

You can buy all of this equipment from The Open Market, The Scrap Dealer, or you can

Fabricate It Yourself if you have the resources and the manpower. motor to operate.

PRINTING THE DATASHEET

You can take a printout of the entire datasheet by clicking on print button

It will look like the following image.

If you want to use the tool for a different combination, you can just change the values inside the input

or refresh the page and follow the same procedure as before and click on submit. Which will show you

the output according to your new values.

UNAVOIDABLE SITUATIONS

Since the tool is designed for small entrepreneurs, it has certain limitations. If you try to enter values

higher than mentioned ahead, you will get an error message

We manufacture Multiple Effect Evaporator from 5 TPD to 50,000 TPD.

You can click on reset to enter new values if you entered the value by mistake.

You can click on contact us if you absolutely need a product with values higher than the specified range

and we will give you a Free Quotation for your Entire System from beginning to end according

to your requirements. If you have any kinds of restrictions such as budget, space, or time limit, we can

even suggest a different type of conveying system that satisfies your needs.

Please do not forget to leave Feedback, it helps improve our services and check out the other types

of products we provide

IMPORTANT SAFETY INSTRUCTION

While it is inspirational to start your own business, you should not forget to read our terms and conditions for your own safety. As you will be manufacturing your own system, we are not liable for any kind of mishaps and failures in your project. We strongly advise taking guidance from us or anyone else with proper knowledge and experience if you are new to the industry or feel even a little bit unsure about any aspect of your project. We hope that you make your decisions wisely.

Related Products

We are Pneumatic Conveying system Manufacturer in India. We manufacture and supply a wide…

We are Dust Collection System Manufacturer in India. We manufacture and supply a wide…

We are Multiple Effect Evaporators Manufacturer in India. We manufacture and supply a wide…